In the rapidly developing electrical industry of the Middle East, where high ambient temperatures, harsh working conditions, and strict requirements for equipment stability and efficiency coexist, selecting the right busbar processing equipment is critical to ensuring the smooth operation of power transmission and distribution projects. The three-station oil-cooled busbar processing machine, with its advanced oil cooling system, excellent temperature adaptability, and high processing efficiency, has emerged as the preferred equipment for electrical manufacturing, power engineering, and industrial installation enterprises in the Middle East. This article focuses on the technical characteristics, temperature adaptation performance, efficiency indicators, and application advantages of this equipment in Middle Eastern regions, providing a professional reference for industry practitioners.

Technical Parameters

Items | Model | ||

303U-3-C | 503U-3-C | 803U-3-C | |

Nominal force (kn) | 300 | 500 | 800 |

Punching dia.range (mm) | ф4.3~ф25 | ф4.3~ф30 | ф4.3~ф34 |

Max.thickness (mm) | 12 | 16 | 20 |

Max.width (mm) | 150 | 200 | 250 |

Max.shearing thickness (mm) | 12 | 16 | 20 |

Max. shearing width (mm) | 150 | 200 | 250 |

Max.horizontal bending width (mm) | 150 | 200 | 250 |

Max.Horizontal bendind thickness (mm) | 12 | 16 | 20 |

Max.vertical bending size (mm) | 10×100 | 12×120 | 12×120 |

Power (kw) | 3×4KW | 3×5.5KW | 3×5.5KW |

Bending precision (degree) | ±1° | ±1° | ±1° |

Repeat bending precision (degree) | ±0.5° | ±0.5° | ±0.5° |

First table size (mm) | 1750×1250 | 1920×1385 | 1920×1385 |

Second table size (mm) | 985×500 | 985×500 | 985×500 |

Outside dimension (mm) | 1780×1400×1300 | 1950×1560×1390 | 1950×1560×1450 |

Container size(mm) | 1870×1480×1520 | 2060×1660×1650 | 2060×1660×1650 |

Total weight(kg) | 1400KG | 1700KG | 2100KG |

LT 3 in 1 busbar processing machine with oil cooling system Busbar Machine Videos:

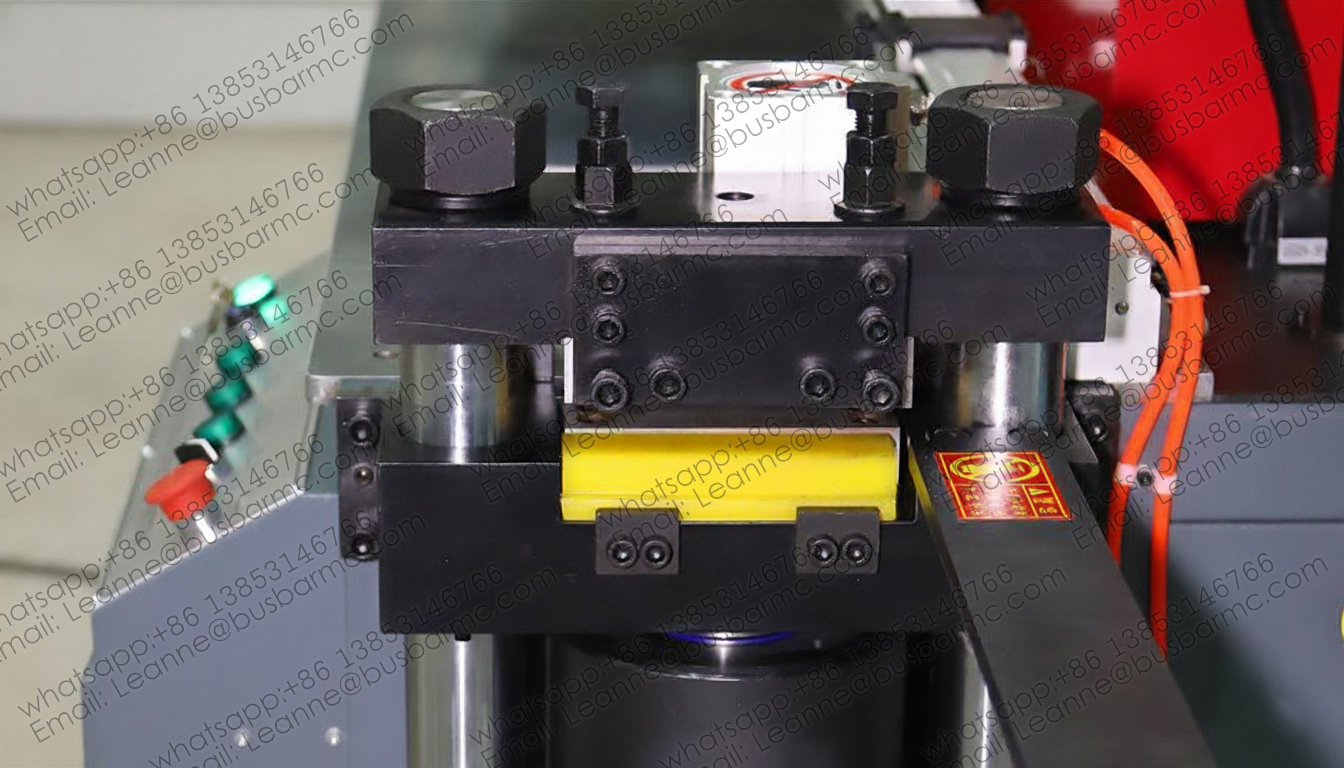

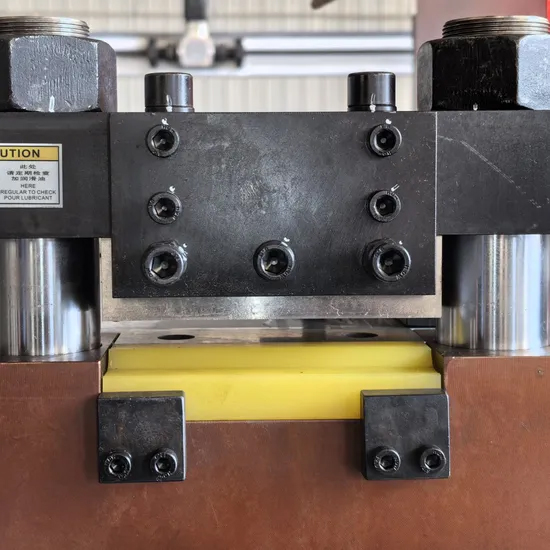

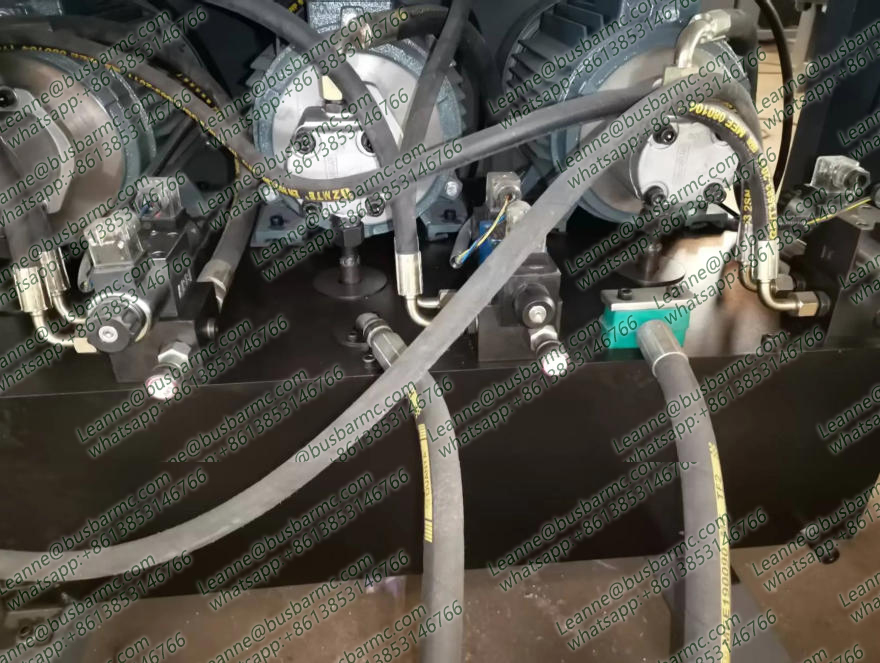

The three-station oil-cooled busbar processing machine is an integrated electrical processing equipment designed for cutting, punching, and bending of copper and aluminum busbars—core components in power distribution systems. Unlike traditional water-cooled models, this machine adopts a high-efficiency oil cooling system, which not only solves the problems of pipeline blockage, freezing, and corrosion caused by water cooling in extreme environments but also optimizes heat dissipation performance, ensuring stable operation of the equipment under long-term high-load working conditions. Its three-station integrated design enables continuous processing of busbars without frequent position adjustment, greatly improving processing efficiency and reducing labor costs, which is perfectly aligned with the efficient production needs of the Middle Eastern electrical industry.

The Middle East is characterized by a typical arid and hot climate, with ambient temperatures often exceeding 40°C in summer and even reaching 50°C in some regions (such as Saudi Arabia, Kuwait, and the UAE). Meanwhile, some remote construction sites may experience large temperature differences between day and night, with minimum temperatures dropping to around 0°C in winter. The three-station oil-cooled busbar processing machine is specially optimized for these climate characteristics, achieving excellent temperature adaptation through scientific structural design and advanced oil cooling technology.

Operating Ambient Temperature Range: -5°C to 70°C, covering the extreme temperature changes of most Middle Eastern regions, without additional heating or cooling equipment to ensure normal startup and operation.

Oil Cooling System Working Temperature: The cooling oil adopts high-temperature resistant industrial oil with a boiling point above 200°C and a freezing point below -20°C, which can maintain stable fluidity and heat dissipation performance in high and low temperature environments, avoiding system failure caused by oil boiling or solidification.

Equipment Internal Temperature Control: During continuous operation, the internal temperature of the machine is stably controlled below 85°C, and the temperature rise of key components (such as hydraulic pumps, motors, and processing dies) does not exceed 35°C. This effectively prevents component aging, lubrication failure, and processing accuracy reduction caused by overheating, extending the service life of the equipment.

Temperature Derating Adaptability: When the ambient temperature exceeds 40°C, the equipment can maintain stable performance without obvious derating; only when the temperature exceeds 60°C, it is necessary to adjust the working frequency appropriately, which fully adapts to the long-term high-temperature working environment in the Middle East.

Anti-Corrosion and Anti-Scaling: The Middle East has high water hardness and high salt content in the air. Water-cooled equipment is prone to pipeline scaling, corrosion, and blockage after long-term use, which affects heat dissipation efficiency and even leads to equipment shutdown. The oil cooling system uses closed circulation, avoiding contact with external water and air, fundamentally solving the problems of scaling and corrosion, and reducing maintenance costs.

Anti-Freezing and Anti-Boiling: In winter, water-cooled equipment needs to add antifreeze to prevent pipeline freezing and cracking; in summer, it is prone to water boiling and vaporization, which affects heat dissipation. The high-temperature resistant and low-temperature resistant performance of the cooling oil ensures that the system can operate stably in extreme temperature environments without additional protection measures, improving the reliability of the equipment.

Stable Heat Dissipation: The cooling oil has excellent thermal stability and uniform heat transfer performance. Even in the case of sudden temperature changes (such as sudden cooling at night after high temperature during the day), it can quickly adjust the heat dissipation efficiency, ensuring that the equipment works at a stable temperature and avoiding processing errors caused by temperature fluctuations.

Processing Speed: The cutting speed is 8-12 pieces per minute (for busbars with a thickness of 3-12mm and a width of 10-120mm); the punching speed is 10-15 times per minute (for common punch sizes Φ6-Φ20mm); the bending speed is 6-10 pieces per minute (for bending angles 0°-180°), which is 30%-50% higher than that of single-station or ordinary three-station water-cooled equipment.

Continuous Working Time: Under the condition of ambient temperature 45°C, the equipment can work continuously for more than 8 hours without shutdown for heat dissipation, meeting the needs of large-batch continuous processing in Middle Eastern industrial plants.

Processing Accuracy: The cutting accuracy is ±0.1mm, the punching accuracy is ±0.05mm, and the bending angle accuracy is ±0.5°, which ensures the dimensional accuracy of the busbar, avoids rework caused by inaccurate processing, and improves the overall efficiency of the project. The processing accuracy remains stable even under long-term high-temperature operation, without being affected by temperature changes.

Energy Efficiency: The motor adopts high-efficiency energy-saving motor, with a power of 7.5-11kW, and the energy consumption is 15%-20% lower than that of ordinary water-cooled equipment. The oil cooling system adopts a variable frequency circulation pump, which can adjust the oil flow according to the equipment temperature, further reducing energy consumption and adapting to the energy-saving requirements of Middle Eastern enterprises.

Three-Station Integrated Design: The cutting, punching, and bending stations are integrated into one body. The busbar can complete three processes continuously without moving between different equipment, saving the time of position adjustment and material transfer, and improving the processing efficiency.

Intelligent Control System: Equipped with a touch screen control panel, which can preset processing parameters (such as busbar size, punching position, and bending angle), support parameter storage and call, avoid repeated parameter setting, and reduce operation errors. At the same time, it is equipped with a fault alarm function, which can quickly locate the fault and reduce maintenance time.

Quick Die Change: The processing die adopts a quick-change structure, which can complete the die change within 5 minutes, adapting to the processing needs of different specifications of busbars, and improving the flexibility and efficiency of the equipment.

Strong Environmental Adaptability: In addition to temperature adaptation, the equipment adopts a dust-proof and sand-proof design, which can effectively prevent sand and dust from entering the internal components, adapting to the sandy and dusty environment in the Middle East. The shell is made of high-temperature resistant and anti-corrosion materials, which can resist the corrosion of high temperature and salt spray in coastal areas (such as Dubai and Qatar), extending the service life of the equipment.

Low Maintenance Cost: The oil cooling system has a simple structure, few wearing parts, and the cooling oil only needs to be replaced once a year, which is less frequent than the water change and pipeline cleaning of water-cooled equipment. At the same time, the equipment has high reliability and low failure rate, reducing the maintenance time and cost, which is very important for Middle Eastern enterprises that pay attention to cost control.

Compliance with International Standards: The equipment complies with IEC (International Electrotechnical Commission) and ANSI (American National Standards Institute) standards, and the processed busbars can meet the technical requirements of Middle Eastern power engineering and electrical equipment manufacturing. It has passed relevant international certifications, ensuring the quality and safety of the equipment in practical applications.

Wide Application Scope: It can be widely used in power plants, substations, electrical switchgear factories, building electrical installation, and other fields, suitable for processing copper busbars, aluminum busbars, and other materials of different specifications, meeting the diverse processing needs of the Middle Eastern electrical industry.